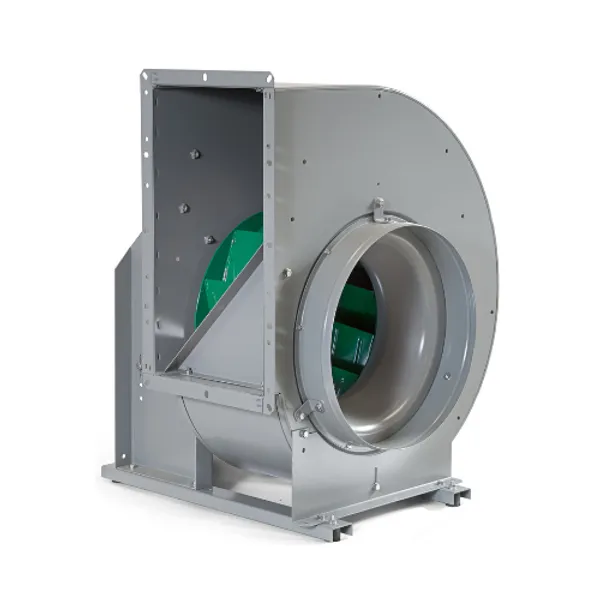

Centrifugal Fans (GTL-1)

The GTL-1 direct driven, single-inlet centrifugal fans cover air flows up to 7 m3/s and pressure rises up to 2000 Pa. The fans are available with different types of impellers:

- Impellers with forward-curved blades (GTLF fans)

- Impellers with backward-curved blades (GTLB fans)

Versions

Besides the normal version, the fans are also available in a sparkproof version. The smoke extraction version of GT has been tested by the French CTICM institute and by the Russian VNIIPO institute. CTICM has tested the fans for +400 °C, 2 hours and the tests cover GTLB-1-025–071 and GTLF-1- 031–050. VNIIPO has tested the fans for +400 °C, 2 hours and for +600 °C, 1 hour and the tests cover all single-inlet GT-fans. The fans in the spark-proof version conform to the German standard VDMA 24 169 3.1 – 3.2 and 3.4. The inlet cone is made of brass. In the GTLF fans, the inlet is fitted with a brass band. If the inlet of the fan is connected to the ducting, the single-inlet fans are rated for continuous operation at temperatures up to +80 °C. If the motor is exposed to the air stream (i.e. on a free-inlet fan), the ambient temperature must not exceed +40 °C. Motors for higher temperatures are available on request.

Design

The casing is made of Sendzimir galvanized sheet steel. The side plates are stamped in one piece and the inlets are deep-pressed in the end walls. The casing is jointed by the “Pittsburg folding method” which produces tight, strong joints. The “Pittsburg folding method” and the deep-pressed inlets ensure a stable design and high, consistent quality. The fan tongue offers optimized aerodynamic properties.

More information about Centrifugal Fans

Don’t hesitate to contact us for more information about our centrifugal fans. Our skilled engineers are eager to explain the possibilities for your vessel.

Download the Centrifugal Fans (GTL-1) brochure for detailed information and technical specifications.

Looking for a custom solution?

Don’t hesitate to contact us for advice for your specific needs.