Noise Control: Part 4 – Reducing HVAC Noise Issues

Noise Control: Part 4 – Reducing HVAC noise issues

– by Peter Koelewijn, 13-06-2018

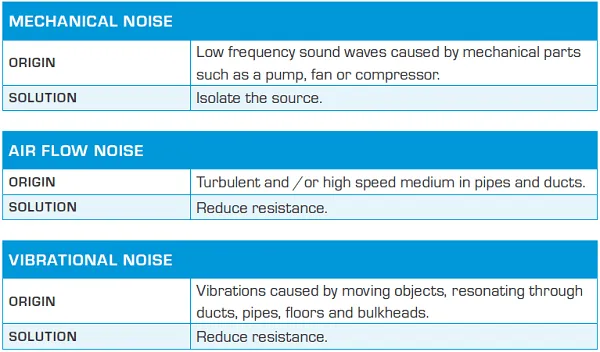

In my last blog we have covered three types of noise which are common in HVAC systems. Our topic for today is to find a solution for each one of them. Although there are different forms of noise, almost every issue can be brought back to three basics. By knowing the solution for these basic problems, you are ready to face every noise problem in the future.

- Blog 1: What is sound?

- Blog 2: What is acoustic comfort?

- Blog 3: Three types of noise.

- Blog 4: How to prevent or reduce HVAC noise issues.

The situation

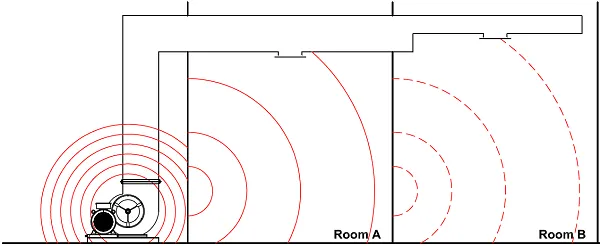

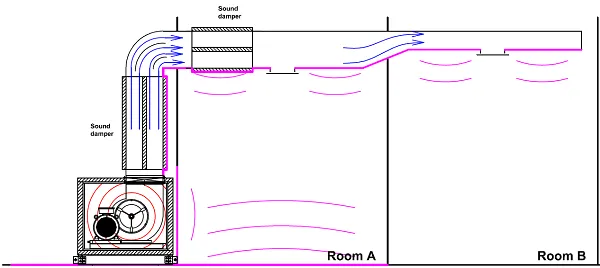

Imagine a situation with two cabins, both supplied with air by a centrifugal fan in the neighbouring room. I am going to use this situation to describe each of the sound issues and their solutions. We will go through every type of noise step by step: first the problem, then the solution. Step-by-step we handle every type of noise. If you want a deeper knowledge about the three noise types, check out blog three, which handles this topic.

Mechanical noise

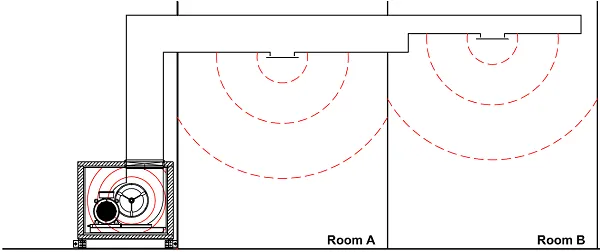

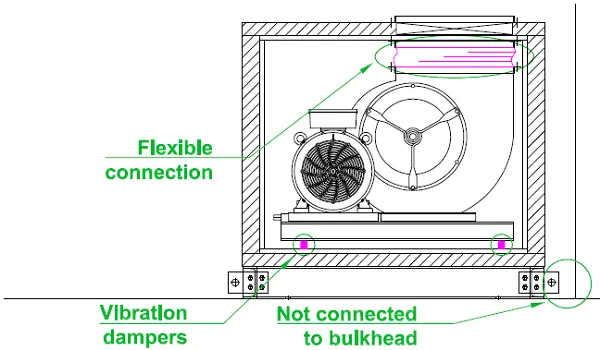

The centrifugal fan is pumping air into rooms A and B. Although the fan is placed inside a separate room, mechanical noise can be heard through the bulkheads, especially in room A, because this room is next to the fan room. The source of the noise is the fan itself, and to reduce the noise, we must insulate the fan. Image 2 shows the same situation with a sound-dampening box. Another option is to insulate the entire room.

Image 1: Mechanical noise

Image 2: Fan placed in sound box

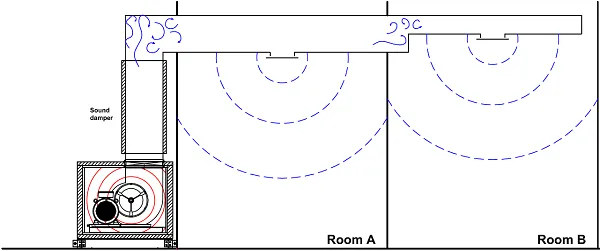

The mechanical fan noise is isolated by the box and soundwaves will not penetrate the bulkhead. However, as the rooms are connected with an air duct, soundwaves traveling through the air supply can still enter the room. To reduce the noise, we can place a sound damper in the duct (see image 3, next page). The longer the damper the better, especially with mechanical noise, as the frequency is low and the wave lengths are long.

Image 3: Air flow noise

Air flow noise

Ideally the air flow is laminar, which means the air molecules travel through the duct in layers. Distortions in the ducting system – such as bends, bottlenecks or HVAC equipment – can cause the air flow to become turbulent (see image 3). Air molecules spin around in the duct, humming and swooshing, which causes air flow noise. Turbulent air can be caused by bad duct design or high speeds inside the duct.

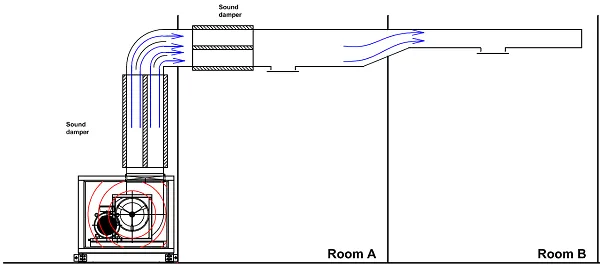

Image 4: Dampers placed in ducting

To prevent air from becoming turbulent, the ducting system has to be adjusted to minimise resistance. For example a

90° bend instead of an angle bend in the system. Make sure the bends are as curved as possible, guiding the air into the right direction while avoiding collisions with the sides. You can also use blades inside the bend to guide the air. Another option is to place a sound damper before and after the bend. Dividing the dampers into different sections forces the air into layers and causes it to become laminar again; see image 4.

Vibrational noise

The source of vibrations is moving parts in the system. The fan rotates at speeds of 3600 rpm and the pressure fluctuates between its air intake and outlet. All these rocesses cause vibrations, which travel through the floor on which it stands and through the ducts, causing them to resonate. In addition, as the fan box is positioned against the wall it makes contact with the bulkhead and transfers vibrations to the adjacent room; see image 5.

Image 5: Vibrational noise

Obviously, we cannot stop the fan from moving. What we can do is stop the vibrations from being transferred to the

surroundings. First of all, we have to make sure the fan box is not connected to anything except the floor: no contact with bulkheads, walls or anything else. Second, we put the fan on vibration dampers to dampen the movement transferred to the floor. And finally, we make sure the connection to the ducting system is flexible. This enables the

fan to move freely without transferring its vibrations to the floor, bulkhead or ducting system. For more details, see image 6.

Image 6: Flexible arrangement of fan

Summary

The discussed solutions are typical for ventilation systems. But the same noise problems

occur in other systems, like the drinking water system, where it’s the circulation pump

that’s responsible for the vibrational & mechanical noise and water that creates

turbulence in the pipes. Another example is a cooling plant, with freon lines and a

compressor – mechanical parts, vibrations and flow.

There are many other possibilities to eliminate noise in your HVAC system. For example, turbulence can also appear when ducts and filters are dirty. The solution is always the same: reduce resistance. There are many ways to reach your goal. Think outside the box and focus on the source of the noise. If you know how it transfers soundwaves, you can find a way to block them. We summarise as follows:

This concludes our blog series on noise control, written to highlight the importance of acoustic comfort in an HVAC system and give a better understanding of the nature of sound. We have seen that conditions like temperature and relative humidity are not the only parameters for a comfortable environment. By knowing the different types of noise, you can find a solution for every HVAC noise problem.

Questions?

If you still have any questions or a specific noise problem with your HVAC system, contact one of our technicians. We will be pleased to help you achieve acoustic comfort in your system.