Noise Control: Part 3 –Three types of noise

Noise Control: Part 3 –Three types of noise

– by Peter Koelewijn, 23-04-2018

In part 1 and 2 of this series of blogs, I have covered what sound is and what acoustic comfort is. When sound is judged to be unpleasant, loud or disruptive to hearing, it is called noise. Super yachts, cruise ships, and even commercial vessels, all are subject to certain noise level requirements. In this blog I am going to explain different types of noise.

- Blog 1: What is sound?

- Blog 2: What is acoustic comfort?

- Blog 3: Three types of noise.

- Blog 4: How to prevent or reduce noise issues.

Wall of sound

A couple of years ago I attended the sea trial of what one would call a super yacht. As the vessel cruised towards its destination the coastline slowly moved away from me. On my way to the galley I passed the engine room and for a moment I stood still before the door. Muffled sounds and squeaky noises where audible through the massive door. Although I had no business there, curiosity incited me to take a look inside. I opened the door and a wall of sound washed over me!

It seemed like this enormous wall of noise was a single sound, like one thundering roar. But when I listened carefully, I could hear different components. I realised this was not just one sound, but a blend of noises all mixed together. There was the pounding of engines, the hiss of pumps and the thundering of air through gigantic ducts near the

ceiling.

The same goes for HVAC systems: walk inside a fan room and you will notice that all the different processes each produce their own noise. If you want to isolate a noise, you first need to identify its origin. Installation technicians separate three different types of noise, namely:

- Mechanical noise;

- Flow noise;

- Vibrational noise.

Mechanical noise

When a fan, pump or compressor is running, electrical energy is transferred into work. Bearings are rolling, pistons pumping and screws turning: the machine is doing its job. As the gears move, there is contact between materials, which causes friction and therefore air pressure difference in the direct vicinity of the machine.

Flow noise

The product of a running fan is the transportation of air through ducts and pipes. Air is a gas that consists of different

molecules, each of which has its own mass and can collide with others to cause friction and turbulence. This is similar to the solid components of a compressor, only on a micro level.

Vibrational noise

As the name implies, these are noises caused by vibrations. While this essentially applies to all sound, even mechanical or air flow noise, we define vibrational noise separately because it can be particularly troublesome. An

example of this type of noise are resonating ducts.

To measure is to know

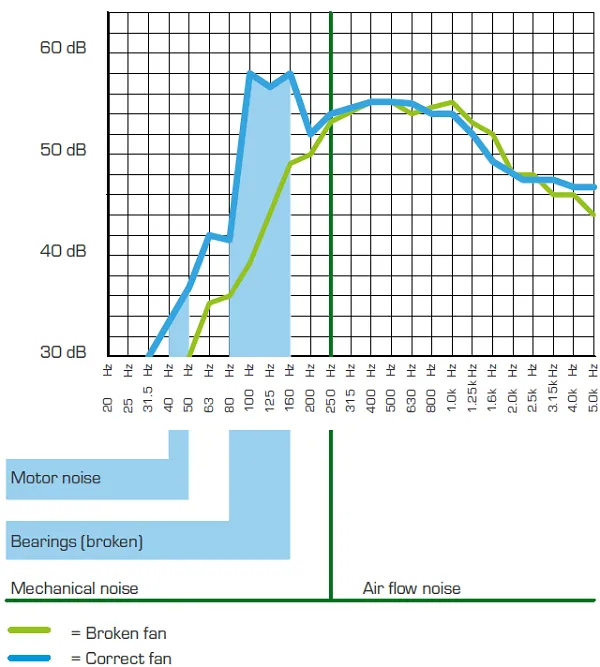

If you have a noise problem somewhere in the cabin or public space, you could listen very carefully and try to localise it. But unless you have excellent hearing, you may struggle to filter out the exact noise you’re looking for. In our previous chapter, we discussed how sounds are defined by their frequency and loudness. We can use these properties to define and localise any particular sound. A spectrum analyser can be used to display loudness as a function of frequency, as shown below.

Image 1: Spectrum analysis

This is an example of a fan. The blue line represents a fan that operates normally. The green line is the same fan but with broken bearings. Notice that the intensity of the latter peaks at lower frequencies. In other words, when you see a peak in loudness at a low frequency, you’re probably hearing a mechanical noise. Disruptive air flow due to turbulence peaks at a higher frequency. A spectrum analyser enables you to pinpoint the type of noise causing the problem. In our final chapter, we will discuss the solutions for all three noise types.

Peter Koelewijn | Sales Manager

Peter Koelewijn has been working at Heinen & Hopman since 2001. Starting out as a mechanic, he gained valuable field experience mounting ducts and pipes for various shipbuilding projects. Five years later he switched to engineering, where he worked his way up from draughtsman, to engineer to site manager, leading teams of HVAC mechanics at one of the largest shipyards in Germany. The last couple of years he has been working as sales manager, combining knowledge from the field and the office to find the best solutions for our customers.