Choosing natural refrigerants: part 1

Choosing natural refrigerants: part 1

– Introduction

Natural refrigerants are a hot topic. More and more onshore utility-based installations are switching to natural refrigerants. What’s the situation in the maritime industry? Selecting the right refrigerant is no easy task as each type has its own pros and cons. In this blog series we will explore the most common natural refrigerants so you can understand which one best suits your specific application.

What are natural refrigerants?

The main advantage of natural refrigerants is their low global warming potential (GWP) – the equivalent CO2 impact on the environment. Natural refrigerants have GWPs ranging from 0 to 3, while the majority of synthetic refrigerants are extreme greenhouse gases with GWPs up to 4000 – yes, that’s 4000 times the equivalent of CO2. It is a common error to presume that natural refrigerants are automatically more energy efficient which, as we shall see, is not always the case. The reason why natural refrigerants are more sustainable is on a whole other level.

How to compare natural refrigerants?

Before we dive in let’s establish the rules of the game. In this series we’ll compare five different refrigerants on a fixed set of properties. Three of them are natural refrigerants, namely, R744 (CO2), R717 (NH3), and R290 (Propane). Then we have R1234ze (HFO), one of the newer synthetic refrigerants with a low GWP. Lastly, we take one of the most used synthetic refrigerants R134a (HFK) as a benchmark.

All starting points are the same for every refrigerant. We compare them on the following temperatures:

Evaporation temperature: -10°C

Condensation temperature: 25°C

Overheating 20K

Subcooling 5K

To give you an honest review and a better understanding, we compare every refrigerant on a fixed set of properties. These are:

| Thermodynamic properties | Safety | Sustainability |

| Temperatures | Flammability | GWP |

| Pressures | Toxicity | Ozone depletion |

| Latent heat capacity | Pressure | Energy efficiency |

| Corrosive |

Why are these properties important? Read on…

Thermodynamic properties

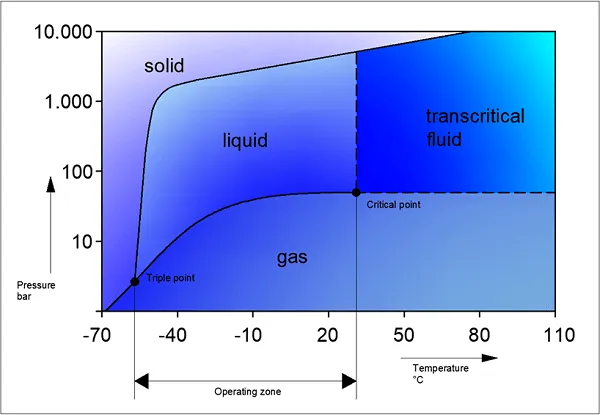

The concept of cooling depends on evaporation and condensation. Each refrigerant has its own specific boiling point and operating zone. The preferred refrigerant for your specific application (air-conditioning, provision cooling, etc.) should fit within the operating zone of this refrigerant.

Figure 1: Phase diagram CO2

Another key factor is the amount of latent energy the refrigerant can absorb before evaporating. This is the energy a refrigerant can absorb or release while the phase changes (liquid to gas/gas to liquid) at a constant temperature and pressure. Fully turned into gas or liquid, the temperature will change with the pressure remaining constant while adding/releasing heat – a process called superheating/sub-cooling.

Safety

Unlike stationary systems on land installations, the cooling plant on a vessel has a far higher leaking ratio. The constant presence of movements (waves) and vibrations (surrounding machinery) make the refrigerant leaks more frequent, with annual refrigerant losses of 20 to 40% reported.

As you know, it’s annoying enough when faced with leakage of synthetic refrigerants, which causes emissions and affects the operation of the chiller. But the damage is even worse with most natural refrigerants as they are asphyxiating, toxic and extremely flammable. This has obvious consequences for the space in which the cooling installation is installed.

Here we review the refrigerant according to the EN378 safety classification, which consists of two sections: A or B followed by 1, 2L, 2 of 3.

- A or B states the toxicity

- Class A has the lowest toxicity

- Class B has the highest toxicity

- 1, 2L, 2 or 3 states the flammability

- 1, non-flammable

- 2L, low flammability

- 2, flammable

- 3, highly flammable

Sustainability

This is the main reason why natural refrigerants are now on the agenda as people strive to reduce emissions and stop global warming due to the greenhouse effect. The high leakage ratios in the maritime sector make the switch to natural refrigerants worth considering.

There are, however, other factors to take into account such as the energy efficiency of the installation. An installation that is more energy efficient obviously consumes less power. A lower load balance reduces CO2 emissions from the fuel burning generator. In addition to the GWP of a refrigerant, therefore, the energy efficiency of a system is a point of interest when it comes to sustainability.

Conclusion

The ability to design an installation that contributes to a cleaner environment is always welcome and natural refrigerants have a part to play. At the same time, we need to be aware of the multiple factors involved in choosing the right refrigerant for your specific application.

Want to learn more about natural refrigerants? You can download our extensive whitepaper here.