MGO Cooler

The MGO Cooler has been developed in response to the MARPOL sulphur emission regulations. Currently, the most widely used fuel in the shipping industry is Heavy Fuel Oil (HFO). Because of its high content in sulphur and heavy metals, sea going vessels burning HFO emit large amounts of air pollutants, and are consequently a major environmental issue worldwide. The MARPOL sulphur emission regulations have been implemented through a series of deadlines that progressively lower the maximum sulphur content of the fuel over years.

Ships sailing in ECA waters have already updated their operations to stricter sulphur limitations in 2010, mainly by switching to Low Sulphur Fuel Oil with a maximum sulphur content of 1.0%. In upcoming regulations the allowed maximum sulphur content will be set to 0.1%. Technically, this is impossible to achieve in a HFO. Therefore, shipping operators currently face a great challenge on how to implement the technical solutions to adapt existing or future installations to the new MARPOL standards.

MGO the only feasible short term option

There are three options to meet the upcoming limitations:

1. Switching to (low sulphur) Marine Gas Oil/Marine Diesel Oil

A safe and proven solution that doesn’t require great investments and it is globally available. The downside of this option is that fuel costs will continue to increase.

2. Using HFO with scrubbers

This solution doesn’t require adapting of fuel tanks or switching to more expensive fuels. However, it is still under testing and installation is expensive.

3. LNG retrofit

This solution reduces CO2, NOx, SOx, and particulate matter emissions. The costs for retrofitting existing ships will be excessive though and there is a lack of bunkering infrastructure.

In the short terms, switching to MGO/MDO is the only reliable alternative at the moment for ships operating in ECA waters.

Operating low sulphur MGO

The refinery process to remove sulphur impacts viscosity and, consequently, lubricity. Operating low viscosity, poor lubricating MGO could cause damage in the engine fuel pump which is designed for high viscosity fuel (HFO) operation.

In order to provide proper film-forming properties to protect pump moving parts from wear, engine manufactures advice to keep a minimum fuel viscosity of 2cSt at the fuel pump inlet. To ensure doubtless operation at start and stop of engines, a viscosity level over 3 cSt is strongly recommended.

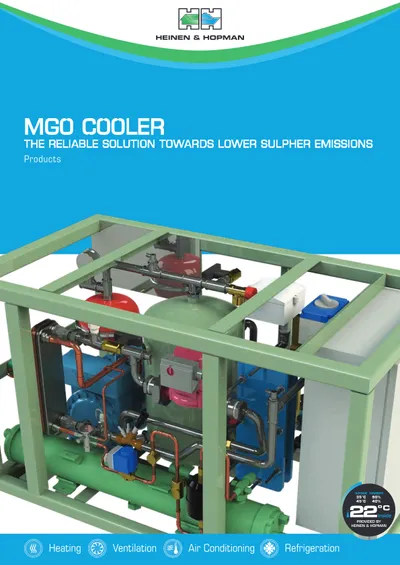

The Heinen & Hopman MGO cooler

Our MGO cooler has been developed based upon decades of experience in successful worldwide sold and operating Heinen & Hopman marine chillers. We have translated our expertise in climate control to fully meet our clients’ needs when adapting their operation to the upcoming emission limitations. Thanks to a precise fuel temperature control, our MGO cooler ensures an optimal protection for any type of engine when fuel is switched from HFO to MGO.

We provide compact units and customized design, easy to retrofit and adapt to any existing or new-build vessel. Furthermore, our worldwide network guarantees that the delivery, installation and maintenance time is always kept to the minimum.

More information about MGO Coolers

Don’t hesitate to contact us for more information about our MGO Coolers. Our skilled engineers are eager to explain the possibilities for your vessel.

Download the MGO Cooler brochure for detailed information and technical specifications.

Looking for a custom solution?

Don’t hesitate to contact us for advice for your specific needs.