Five things you need to know about chilled water systems

– Albrand Velthuizen, 24/05/2019

You may already know that chilled water is the icy lifeblood of the HVAC system. But why is it so important? And which parts of the system need special attention? How does one keep the installation healthy and in good shape, preventing problems? Here’s what you need to know.

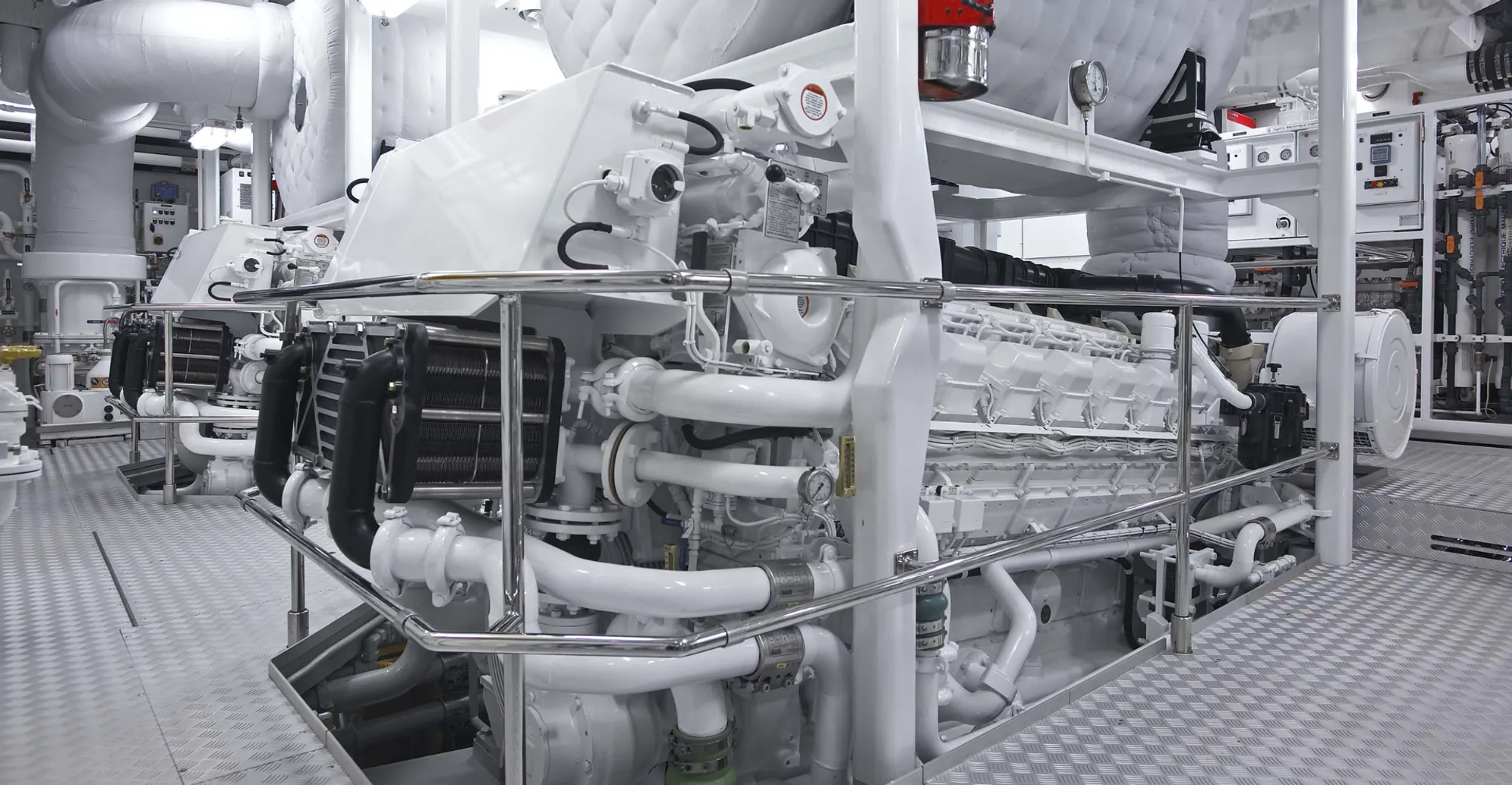

The temperature range of a chilled water system is 6 to 12 °C or 5 to 11 °C, with a temperature difference of six degrees. Chilled water is produced by a chiller – in other words, it’s created artificially. The chiller can be seen as the heart of the system, and the chilled water pipes as its arteries. The pipes weave throughout the entire vessel, from the tender garage to the wheelhouse and from the bowthruster room to the radar systems inside the mast.

1.The importance of glycol

The water inside the pipes is a mixture of water and glycol, a product that prevents the water from freezing. The higher the proportion of glycol in the system, the lower the freezing point of the mixture: for example, a 10% glycol content lowers the freezing temperature to -4°C. Besides protecting the water from freezing, glycol also protects the pipes themselves: being slightly greasy, it leaves a film on the inside of the pipes, protecting them against corrosion.

2.Lowering specific heat

The chilled water acts as an energy carrier as it flows into the heat exchangers of fan-coil units and cooling coils of air-handling units and air conditioners. Here, it pulls heat out of the environment and brings it back to the chiller, where it is cooled. Pure water naturally has a high specific heat capacity (the amount of energy that needs to be removed to lower its temperature). The more glycol there is in a system, the lower its specific heat capacity will be.

3.Water adjustment

In addition to specific heat and temperature, the capacity of a cooling coil depends on the flow of the medium, that is, the amount of chilled water that flows through the pipes. When a fan-coil unit in a tender garage, say, no longer cools, this can be a sign of a flow problem. You may be able to prevent this by adjusting the installation to correct functioning. A properly commissioned installation ensures that chilled water is well distributed among the users as well as preventing cavitation and noise problems.

4.Air issues

One of the most frequent problems with chilled water is air inside the system, which manifests as small bubbles collected in pockets. These prevent the flow of water and leave the heat exchanger dry so that it no longer cools. This is especially common after a new vessel has just been delivered and the chilled water still contains a lot of air. Placing automatic air filters prevents this from happening. It’s important to note that the position of the filters is crucial to their correct operation. Air is lighter than water, so it will tend to collect in more elevated parts of the system. To ensure the best results, the filter needs to be placed on the highest deck.

5.Filtering the system

Although the chilled water lines are thoroughly flushed before operation, there will always be some smudge inside the lines, for example coming out of heat exchangers mounted inside air-handling units. Using filters prevents particles in the chilled water from causing wear to components or blocking narrow pipes. Available filters range from solid-pipe filters to advanced filtration units which even filter air and keep pH levels up.

Like to know more about filtration units or some of the other topics mentioned in this blog? Check out the links below.

Albrand Veldhuizen | Commissioning Engineer

Albrand has been working at Heinen & Hopman since 2006. He has worked himself up to the position of Commissioning Engineer and nowadays he is stationed at one of the largest yacht builders in Germany. During his many years working onboard numerous luxury yachts, he has developed a great expertise in HVAC systems for superyachts.