Sustainability: Waste heat recovery

Sustainability: Waste heat recovery

Mark van Tamelen – 24/06/21

One of the most obvious ways to reduce our ecological footprint is to recover the heat that has already been generated by other activities. The thermal energy stored inside this heat can be used to fuel other processes, making double use of a single power source. Besides heat, also cold can be recovered and reused. How this works you will read in this blog.

Most maritime diesel engines have an efficiency of only 50%, with the remaining energy released from fuel combustion being lost to the atmosphere in the form of heat. Add to that the heat dissipated by the engine and generator cooling systems and you have a large amount of free thermal energy available. It is obviously a shame to let this go to waste but how can you most effectively use it to your advantage?

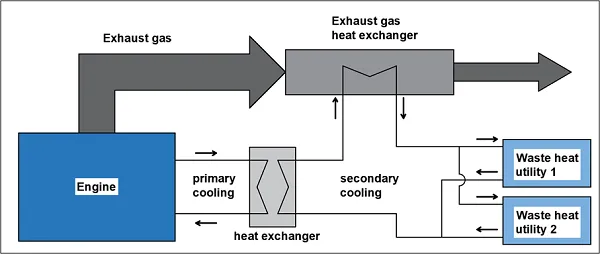

Figure 1: Simplified diagram of how to extract waste heat

Using a secondary system with heat exchangers and water as an energy carrier, heat from the engine cooling system and/ or the exhaust gasses can be extracted and used for other purposes. Think of hot water boilers, HVAC heaters and absorption cooling.

Boiler heating

A good purpose for residual heat is the hot water used for sanitary utilities such as showers, baths and sinks. With a heat exchanger, thermal energy is redirected from engines/generator cooling and exhaust fumes. Water is heated and stored in massive boilers of up to 1000 litres.

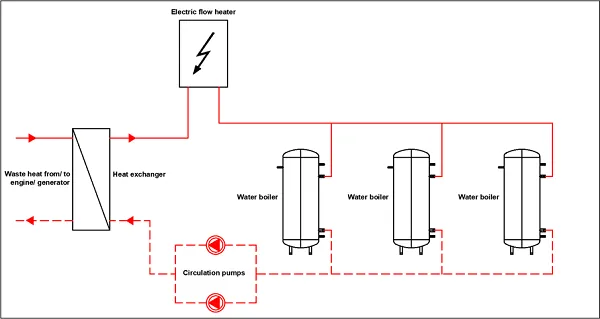

Figure 2: Simplified diagram of waste heat recovery for hot water heating

Backup is provided by separate electric boilers or an electric flow heater, although this is only used in exceptional situations such as when the vessel is on shore power. Residual heat fully covers the heat demand most of the time.

HVAC heating

A significant amount of energy is needed to warm up cooled air inside the air handling units and therefore this is an ideal purpose for a waste heat recovery system. In this system water is used as an energy carrier with the heating coils in the air handling unit serving as a water-fed air heater. A combination of heat exchangers and electrical circulation pumps extracts the thermal energy from exhaust gases and the engine/generator cooling system.

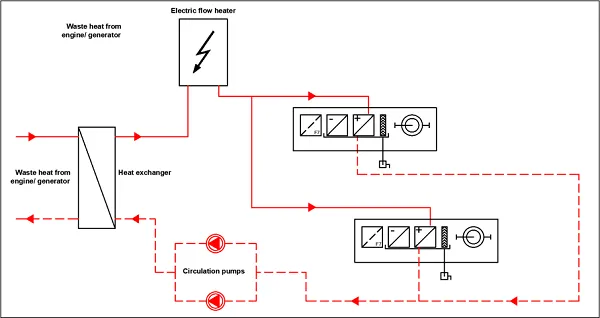

Figure 3: Simplified diagram of waste heat recovery for HVAC heating

Up to 100% of the heat demand is covered by the residual heat from the generators and engines, both pre-heating and re-heating. As a backup, electric flow heaters have been added to the system that step in on the rare occasions when the generator is not running.

Absorption cooling

The essence of an absorption cooling machine is to use (waste) heat to create cold. An absorption cooling machine does not have a compressor – the component responsible for the biggest part of energy consumption in a regular cooling machine. Instead, it uses heat recovered in the same way as the hot water and HVAC heating to power up the process.

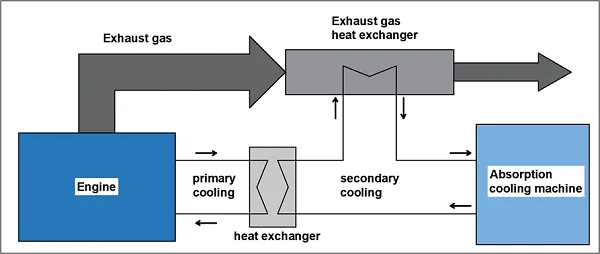

Figure 4: Simplified diagram of waste heat recovery for absorption cooling

While absorption cooling machines have very high efficiencies they can only be used when waste heat is available. Absorption chillers are therefore only used as an extra cooling measure in addition to conventional cooling machines.

Another way of energy-efficient cooling is found on LNG-powered vessels. Liquid Natural Gas is stored on the vessel in tanks where the temperatures are -160°C. The liquid fuel must change phase to gas and is therefore heated before entering the ship’s engine. Some of this cold can be recovered and used for chilled water systems, provision cooling and freezers.

Here we speak of waste cold recovery. Just as is the case with absorption cooling, the capacity is only available as long as the engine is running.

Conclusion

Energy consumption is high onboard vessels, especially commercial vessels like RoPax and Cruise vessels. One of the highest energy consumers on these vessels is the HVAC system. Waste heat recovery is an excellent measure to improve energy efficiency. The thermal energy is used to warm up the boilers for hot water plus the pre-heating and re-heating in air handling units. Although extra heat exchangers and circulation pumps are needed, the complete heat demand is covered in most of the cases. Waste heat can also be used to power up an absorption cooling machine, providing chilled water.

Mark van Tamelen | Senior project engineer

Mark van Tamelen joined Heinen & Hopman in 2000. He started as a drafter in the Dutch yacht division and expanded his field of operation over the years to the export department. He now takes care of specific unique projects with enthusiasm and devotion, key characteristics for which all H&H’s employees are known.